Tipos de calzado de seguridad industrial

Qué es el calzado de seguridad industrial

Los diferentes tipos de calzado de seguridad industrial son parte de un EPI que debe llevar todo trabajador cuando realiza una actividad que conlleve un determinado riesgo.

Son elementos que están regulados por ley, y por tanto, en algunos casos pueden ser obligatorios.

Pero ¿cuál elegir en función de su clasificación?

Clasificación del calzado de seguridad

El calzado de seguridad industrial está regulado por la norma UNE EN ISO 20345.

En ella, de forma general establece dos clasificaciones en función de los materiales con los que hayan sido fabricados:

- Clasificación I: Está formada por aquel calzado de seguridad hecho de cuero y materiales similares.

- Clasificación II: Es la que comprende el calzado realizado a base de topo polimérico o cualquier tipo de caucho.

Para diferenciar los diferentes tipos se incluyen determinados prefijos en sus etiquetas de fabricación, y que deben estar a la vista para poder identificar sus distintas propiedades.

De acuerdo a esto, se establece la siguiente clasificación de calzado de seguridad:

- SB: Incluyen modelos fabricados con materiales de la clasificación I y II. Llevan puntera de seguridad resistente hasta 200 J.

- S1: A las propiedades de los SB, hay que añadirles que son antiestáticos, el tacón se encuentra cerrado y presentan una absorción de energía.

- S2: Son los S1 más una impermeabilidad y resistencia a la penetración.

- S1P: Llevan las características de los S1 más una resistencia en la suela a la penetración (P).

- S3: Son los S2 + resaltes en la suela + una resistencia de penetración en ella (P).

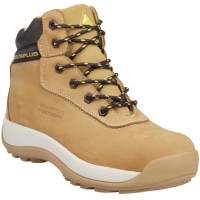

Bota trabajo SAGA S3 SRC

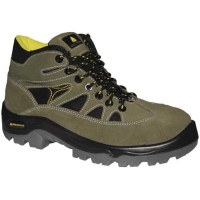

Botas serraje Auribeau3 S1P SRC

Calzado Laboral Microfibra S2 SRC Miami

Zapatillas deportivas seguridad Goal S1P HRO SRC

Zapatos piel flor TW302 S3 SRC

Todos estos pertenecen al tipo I de la clasificación.

En el tipo II nos encontramos con:

- S4: SB + absorción de energía en el tacón + antiestáticos.

- S5: S4 + suela con resaltes + resistencia de penetración en la misma.

Todos estos sufijos establecen unas propiedades comunes por categorías, pero, además, pueden llevar otra letra que designe otras añadidas en ellos.

Por citar algunas, tenemos:

- SR: Suela antideslizante.

- WR: Resistentes al agua.

- E: Absorción de energía en el talón.

- P: Resistentes a la perforación.

- CR: Resistencia al corte.

- HRO: Suela que resiste altas temperaturas.

- FO: Suelas que resisten combustibles y aceites.

- CI: Suela aislante al frío.

- HI: Suela aislante al calor.

Cómo debes elegir el calzado de seguridad adecuado

Cada actividad laboral conlleva unos riesgos específicos y deben ser analizados correctamente para preservar la salud de los trabajadores.

El RD 773/1997 recoge las diferentes medidas que deben tenerse en cuenta para proteger la seguridad y salud de las personas que trabajan en cada actividad laboral.

Al mismo tiempo, indica en función del trabajo cuándo es obligatorio el uso de los diferentes tipos de calzado de seguridad industrial.

Por lo que, en función de los diferentes riesgos, es como debe realizarse la elección del calzado de seguridad apropiado.

Y, además, es la empresa la que tiene la obligación de proporcionarlos a los trabajadores.

En resumidas cuentas, los diferentes tipos de calzado de seguridad industrial se clasifican en función de los materiales con los que están realizados y las diferentes propiedades protectoras que pueden tener.

Cada uno de ellos contiene un sufijo que expresa todas estas características, y que permite una elección correcta teniendo en cuenta los riesgos específicos de la actividad laboral.